Products

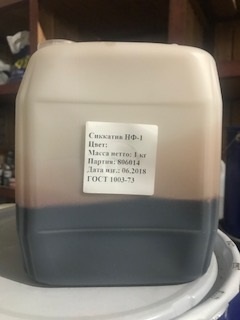

Hardeners Sikkativ NF-1M

October 2, 2018

Hardeners Izur

October 2, 2018Diur hardeners

Active additives to paints and varnishes that allow drying and curing of enamels and hot curing paints under normal conditions without using a drying chamber. They are solutions of low-volatile urethanes containing functional groups of high reactivity in anhydrous organic solvents. Unlike drying accelerators, they come into direct action with paints and varnishes, while at the same time increasing their operational characteristics.

“Diur” and “Diur-Extra” are capable of curing at 200 ° C most of the paint and varnish materials classes: melamine-alkyd (ML), ureteloalkidny (MCH), epoxy (EP), urethane (UR), a number of acrylic (AK), alkyd (GF and PF ) etc.

The use of “Diura” and “Diura-Extra” allows you to:

- To make repair and primary painting of cars inexpensive and affordable;

- Get a quality paint coating without the use of a drying chamber;

- Use high-quality domestic enamels and soils, which harden without a hardener at a temperature of at least 110-130 0 С;

- Paint a number of plastic parts of the car;

- Car repair paint work without disassembling the car and removing the rubber and plastic parts;

- Save energy by reducing the temperature in the drying chamber;

- To paint wooden, concrete, plastic and metal industrial and building structures, as well as large motor transport equipment;

- Increase adhesion and hardness and improve other physical and mechanical characteristics of paint and varnish coatings;

- Save time on painting.

“Diur-Extra” contains special substances that stabilize color. Thanks to them, it has a high resistance to yellowing during storage. These additives also protect enamels from the effects of external factors, primarily from light aging, during their entire service life. This is the fundamental difference between “DIUR-Extra” from “DIUR” and other known hardeners of this type.

The use of “Diura-Extra” when painting with enamels and paints of white color and light shades allows almost to eliminate the effect of yellowing during their use.

Инструкция по применению:

Обычный расход «Диура» -8-10% от массы неразбавленной эмали. С таким количеством отвердителя время полного высыхания и отверждения эмалей при 200 С составляет 3 часа (при 800 С – 40 минут). Уменьшение дозы до 5% отвердителя приводит к соответствующему удлинению процесса отверждения, но не к ухудшению качества покрытия. В тоже время передозировка «Диура» нежелательна, так как это влечет за собой повышение хрупкости отвержденой эмали.

The viability of enamels after displacement with “Diur” at 200 C for at least 8 hours. Enamel after thorough mixing with “Diur” is recommended to sustain for 20-30 minutes. During this period, the removal of bubbles of carbon dioxide emitted as a result of interaction with water, the traces of which are always present in the paintwork material. Solvents used to dilute enamel may also contain moisture. Therefore, it is better to dilute the enamel to the working viscosity with solvents before entering the hardener, and not vice versa. If these recommendations are not followed, the process of isolating bubbles and drying will occur simultaneously, which ultimately can lead to the presence of defects in the form of shells on the enamel.

To dilute the enamels before curing, use anhydrous solvents that do not contain alcohols and other active ingredients. These are white spirit, various solvents and nefras, xylots, toluene, ethyl acetate, butylocetate, acetone, cyclohexanone, turpentine, and mixtures thereof.

It is necessary to store “Diur” at a temperature not higher than 300 ° C in a tightly closed container, preventing water from entering. In an open container after a few hours, it forms an insoluble precipitate under the action of moisture in the air, which is not suitable for further use. For the same reason, in order to obtain a high-quality paintwork, it is undesirable to carry out work with the use of “Diur” in wet weather or at high humidity.

All work with “Diur” must be carried out in the open air or in a well-ventilated room in compliance with fire safety measures. In case of contact with skin, wash immediately with soap and water, and if it comes into contact with eyes – plenty of water. In the case of bottling – fill with sand or sawdust. Washing of spray guns and other paint and varnish equipment with solvents immediately after the completion of painting works in order to avoid hardening of enamel residues.

Use of

“Diura-Extra” is carried out in full accordance with this instruction.